Our History

Checkered Past Machine got its start in the motorsports industry. This industry has a large demand for high quality, accurately machined products, with quick turn-around times. As our success grew in this industry, we began to see our network of customers expand into other industries. Throughout our early years, our only marketing methods were the referrals from our customers. Our quality of work and customer relationship was all that was needed to grow into the company we are today. We now provide service to nearly all major industries throughout the United States and abroad. Throughout the years, we have developed a wealth of knowledge and experiences and now employ some of the most skilled and talented individuals in the manufacturing industry. Early on, we focused primarily on complex prototyping and small volume production. In our more recent years, we have seen a demand for high volume, domestically produced goods. By applying our past experiences of various materials and product requirements, we were able to quickly adapt to this increasing demand. We now offer engineering, automation, and programming services. If you have physical products to machine, no matter the size, volume, or material, we can bring ideas to the table to get you into production.

Testimonials

“We have been using Checkered Past for the last 5 years. No job is too big or too small for them to handle efficiently, with fair pricing and on-time delivery. We have thrown jobs at them that others wouldn’t touch, and they have always come through for us. I would recommend them without reservation.”

“Checkered Past Machine has been an outstanding company for us to work with. No matter if it’s one prototype, or spec parts for use for all the teams, they have never missed with their design help or delivery times. They understand their customer’s wants and needs and are a great group to work with.”

“Checkered Past has been a great partner to work with, they have taken their engineering knowledge and developed processes to streamline the supply chain for Banjo. Their knowledge and partnership to assist on all requests from Banjo is very important to me in accomplishing our goals of a streamline Supply Chain that works. Checkered Past Machine is a big part of our success.”

“Checkered Past Machine consistently impresses us with their can-do attitude when challenged. Parts arrive on time and to our required high quality. They have become an important partner to us at Xtrac.”

“We know whom to go to when we need special ground support tooling produced.”

“Checkered past has been the best. They are helpful and very professional. They have been able to

make a lot of parts for us over the years and have been very helpful in emergency situations too.”

Our History

Checkered Past Machine got its start in the motorsports industry. This industry has a large demand for high quality, accurately machined products with quick turn-around times. As our success grew in this industry, we began to see our network of customers expand into other industries. Throughout our early years, our only marketing methods were the referrals from our customers. Our quality of work and customer relationship was all that was needed to grow into the company we are today. We now provide service to nearly all major industries throughout the United States and abroad. Throughout the years, we have developed a wealth of knowledge and experience, and now employ some of the most skilled and talented individuals in the manufacturing industry. Early on, we focused primarily on complex prototyping and small volume production. In our more recent years, we have seen a demand for high volume, domestically produced goods. By applying our past experiences of various materials and product requirements, we were able to quickly adapt to this increasing demand. We now offer engineering, automation, and programming services. If you have physical products to machine, no matter the size, volume, or material, we can bring ideas to the table to get into production.

Our History

Checkered Past Machine got its start in the motorsports industry. This industry has a large demand for high quality, accurately machined products with quick turn-around times. As our success grew in this industry, we began to see our network of customers expand into other industries. Throughout our early years, our only marketing methods were the referrals from our customers. Our quality of work and customer relationship was all that was needed to grow into the company we are today. We now provide service to nearly all major industries throughout the United States and abroad. Throughout the years we have developed a wealth of knowledge and experience, and now employ some of the most skilled and talented individuals in the manufacturing industry. Early on, we focused primarily on complex prototyping and small volume production. In our more recent years, we have seen a demand for high volume, domestically produced goods. By applying our past experiences of various materials and product requirements, we were able to quickly adapt to this increasing demand. We now offer engineering, automation, and programming services. If you have physical products to machine, no matter the size, volume, or material, we can bring ideas to the table to get into production.

Industries

We Service

Aerospace

Agriculture

Aircraft

Maintenace

Automotive

Defense

Food

Processing

Medical

Devices

Motorsports

Why Choose Us?

Checkered Past Machine is the premier custom manufacturing company in the Midwest. We are made up of strong, forward thinking individuals, with diverse technical backgrounds. Our team has found great success designing and manufacturing goods for the most demanding industries of today. With our experience of robotic systems and PLC’s, we have the in-house capabilities to design, develop, and implement fully automated manufacturing processes. This gives us the upper hand at delivering your products at shorter lead times and competitive prices.

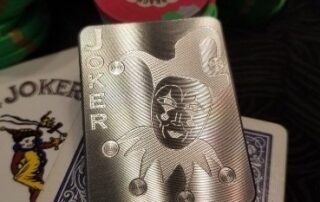

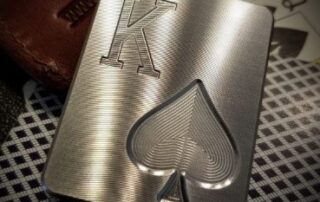

Specialty items

Our customer needed a heavy but sophisticated series of items that would achieve the goal of eliminating the risk of a player’s cards being “mucked”. Checkered Past Machine worked with the customer to define the requirements, the artwork varieties, and generated a few prototypes using 300 series stainless steel. This material selection provides good machineability, outstanding visual finishes, and lifetime “wash & dry” durability in virtually any conceivable environment a poker player might experience.

To purchase Muck Monkey products, please visit https://www.muckmonkeys.com.

Equipment List

Turning Centers:

1) Okuma LB3000EX2 – 48” bar feeder – 3” bar capacity – 18.5” max dia. – Y axis shift – Live tooling – Sub spindle.

7) Haas ST10’s – 1.75” bar capacity – 12” max dia.

1) Haas ST10 – 48” bar feeder – 1.75” bar capacity – 12” max dia.

1) Haas ST20SSY – 48” bar feeder – 2.5” bar capacity – 13” max dia. – Y axis shift – Live tooling.

1) Haas SL30 – 48” bar feeder – 3.5” bar capacity – 17” max dia.

Milling Centers:

1) Smart SM1565 (Awea) – X axis: 59”, Y axis: 26”, Z axis: 24”.

1) Haas Mini Mill – X axis: 16”, Y axis: 12”, Z axis: 10”.

1) Haas VF-2YT – X axis: 30”, Y axis: 20”, Z axis: 20” – with 4th axis option.

1) Haas VF-3 – X axis: 40”, Y axis: 20”, Z axis: 25” – with 4th axis option.